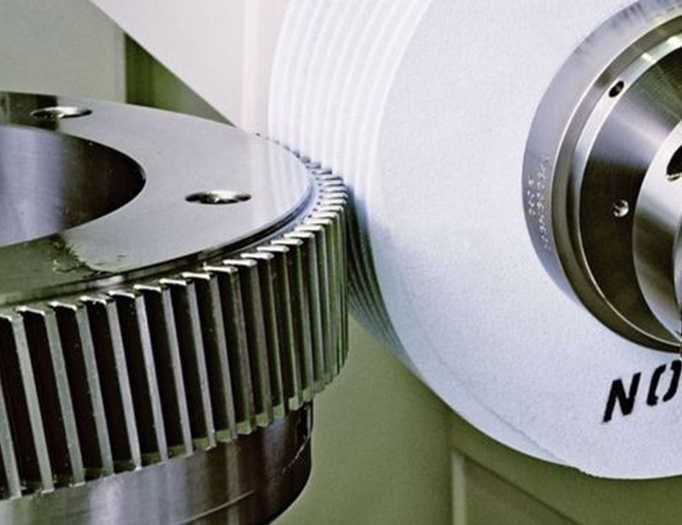

Surface grinding is a widely used abrasive machining process in which a spinning wheel covered in rough particles (grinding wheel) cuts chips of metallic or nonmetallic substance from a workpiece, to produce a smooth finish on flat surfaces. Surface grinding is the most common of the grinding operation. It is a finishing process that uses a rotating abrasive wheel to smooth the flat surface of metallic or nonmetallic materials, to give them a more refined look or to attain a desired surface for a functional purpose. Typical workpiece materials include cast iron and mild steel.

Components having complex geometries or featural relationships which cannot be managed by the centerless grinding process lend themselves well to precision CNC ID/OD grinding, although, given its broader scope of set up, is generally less economical then the centerless method.

Precision ID/OD grinding provides better part-to-part consistency over similar, alternative turning processes, especially for parts with size, roundness, concentricity, and surface finish requirements.

© 2020 All rights reserved speed. Powered by Globosoft

Mobile : (91) 99473 82897 | (65) 9688 4855

Email : sales@speed-tool.com

Website : www.speed-tool.com